During the warranty period of the new car, the substitute of the filter (filter element) should not be used. Even after the warranty period, the filter must be carefully selected. The performance of the diesel filter has a grade code according to the ISO standard. In addition to the performance test according to the SAE standard, the air filter element must be subjected to a bench test to meet the original intake resistance of the engine's rated intake air. Qualified

oil filter must meet the original design of engine cylinder pressure, oil temperature, flow, viscosity and vehicle operating conditions, etc., and the comprehensive balance of core quality must be considered. The hydraulic oil filter element is marked on the manufacturer's product sample or nameplate as the nominal filtration accuracy, not the absolute filtration accuracy. Only the beta value determined by the pass test can indicate the filtration capacity of the filter. The hydraulic oil filter element should also meet the pressure loss requirements (the total pressure difference of the high-pressure filter is less than 0.1PMa, and the total pressure difference of the return oil filter is less than 0.05MPa) to ensure the optimization of flow and filter life.

When selecting the filter (filter element), you can choose the original one or the second brand. It should be noted that the selected filter element should be checked and accepted to check whether it meets the performance indicators it should have.

1. The air filter element selected for the air filter element must match the power, economy and reliability of the original engine.

(1) The air chlorine flow rate in the technical parameters of the rated air intake filter element should be greater than the rated air intake of the equipped engine.

(2) The filter material has requirements on the filter material's thickness, tension resistance, original air intake resistance, and filtration accuracy. Imported diesel engine requires air filtration accuracy of 5μm, domestic diesel engine should also be less than 20μm. The filtration accuracy of high-efficiency filter paper is 2μm, ordinary imported filter paper is 30μm, and domestic filter paper is only 80μm.

(3) Filter element performance test:

① Flow-resistance (pressure drop) test Determine the air flow pressure loss (flow-resistance or flow-pressure curve).

②The original filtration efficiency test can calculate the dust collection efficiency of the filter element, and the dust reduction rate of the normal filter element should be more than 99%.

③Dust storage capacity test and cumulative efficiency test. Excessive dust accumulation in the filter element causes blockage and increases air intake resistance. The air intake resistance when the engine power is reduced by 5% or the fuel consumption is increased by 5% is a limit value. When this value is reached, the filter element must be cleaned or replaced. During the test, the dust weight when the air intake resistance or pressure drop reaches 7-46kPa is the dust storage capacity of the filter element, and the filtration efficiency during this test is the cumulative efficiency.

④Original intake resistance test. When the intake resistance 9 is rated, the pressure difference between the inlet and outlet when the air volume passes through the filter element) should not exceed 3.2kPa, and the power will drop and the engine will emit black smoke.

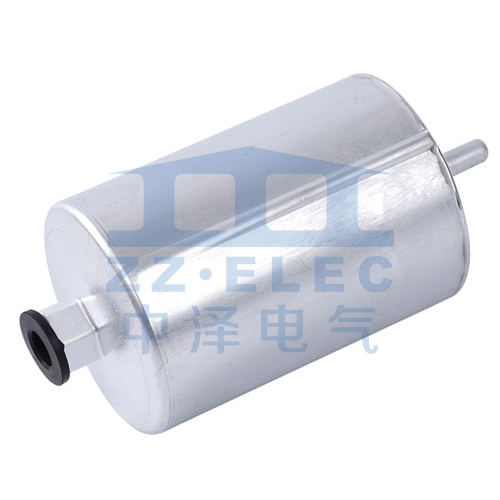

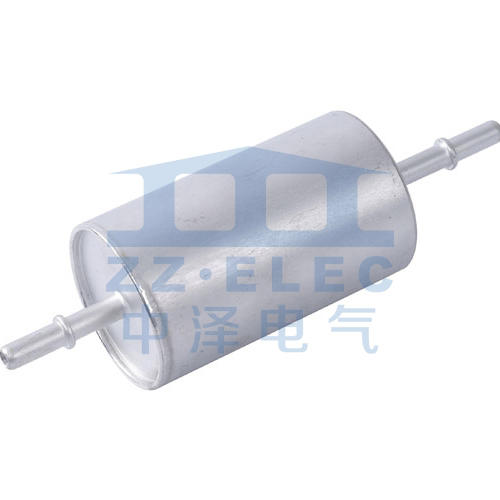

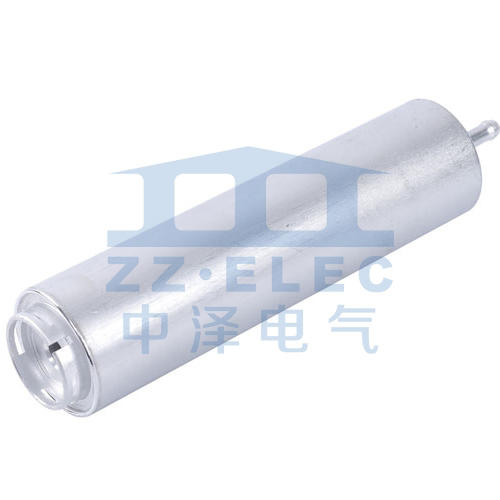

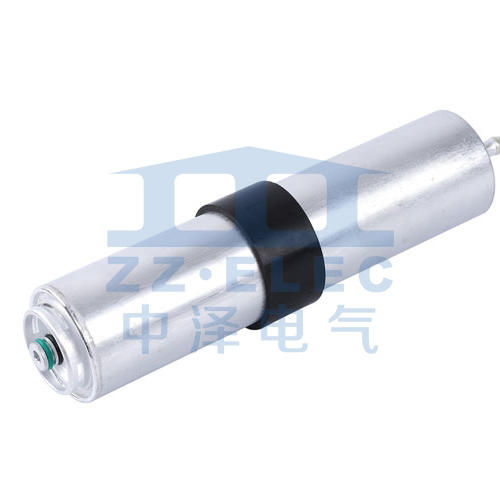

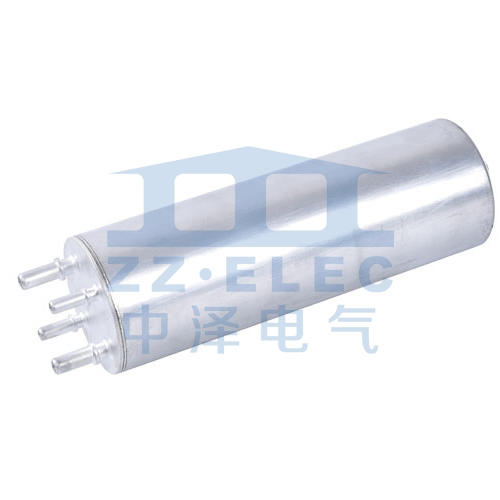

2. Diesel filter Diesel filter should be tested as follows according to ISO4020 standard (road vehicles-fuel filter test method for automobile diesel engine).

(1) The cleanness test of the new filter determines whether the inner side of the filter element has been removed from the dust and impurities remaining in the production, storage and transportation.

(2) The bubble method test is used to confirm whether the filter element has pores larger than the filtration accuracy.

(3) Filtration efficiency and life test Filtration efficiency refers to the determination of the percentage of specific particles that are filtered out, and the filter life is expressed as the time when the plugging test pressure difference is greater than 0.07MPa.

(4) The water separation validity test determines the percentage of water in the oil-water mixture separated by the oil filter.

(5) Filter element damage test to determine the rupture pressure of the filter element.

(6) The oil filter assembly damage test determines the ability of the assembly to withstand internal pressure.

(7) The pulsating pressure fatigue test measures the mechanical strength of the oil filter assembly under pulsating pressure (simulating engine start or stop).

(8) The anti-vibration fatigue test determines the mechanical strength of the oil filter against vibration under normal use conditions.

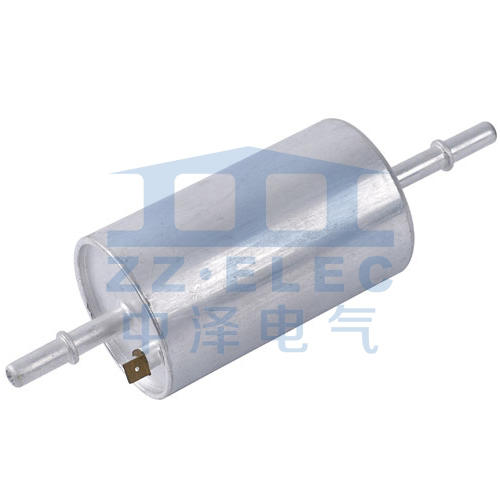

3. The full-flow oil filter of the oil filter shall be subjected to the following tests in accordance with the ISO4548 standard.

(1) Pressure drop-flow characteristic test Use oil of specified viscosity to determine the pressure drop-flow curve of the oil filter assembly.

(2) The characteristic test of the filter element bypass element is to determine the filter element pressure drop-bypass flow curve. When the pressure drop through the filter element is low, in order to limit the amount of unfiltered oil, when the bypass element is lower than the specified opening pressure drop, a small amount of oil leakage is allowed; and when the filter element is completely blocked, it can be bypassed Pass the full flow without exceeding the specified pressure drop.

(3) High pressure drop and high temperature characteristic test The oil filter will experience high pressure drop during operation (especially when the filter element is blocked). In addition, the filter element is also affected by the high temperature of the oil, and the ability of the filter element to withstand high pressure drops without being damaged should be tested under simulated high temperature conditions.

(4) The filter element life and filtration efficiency test uses the particle counting method to determine the filter element. During the test, draw the relationship curve of pressure difference-test time or pressure difference-ash weight to achieve 75% of the design opening pressure of the bypass valve. Or the weight of contaminants to indicate the life of the filter element.

(5) When the cumulative efficiency test uses gravimetric analysis to determine the life of the filter element, it is evaluated by the test time when the end-point pressure difference is reached or the amount of pollutants captured.

(6) The hydraulic pulse fatigue test oil filter is subject to the fluctuating pressure in the engine cooling state during use. During the test, use the specified pulsating oil pressure to cycle 1000 times to determine the pressure resistance of the oil filter housing, seal ring and filter element against high pressure fluctuations.

(7) Vibration fatigue test After installing the machine stain filter assembly, add the frequency and amplitude of resonance caused by the vibration surface of the engine or installation structure, maintain the specified oil pressure, and cycle 10 million times to ensure that there is no small leakage Oil stains or fatigue damage performance.

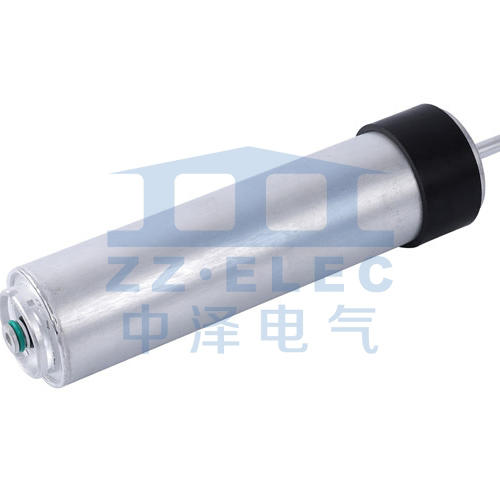

4. Hydraulic oil filter element

(1) Filtration accuracy First, determine the cleanliness level of the stains according to the needs of the hydraulic system, and then select the filter accuracy of the oil filter according to the table according to the cleanliness level. The most commonly used hydraulic oil filter element in construction machinery has a nominal filtration degree of 10μm.

Since the nominal filtration accuracy cannot truly reflect the filtration capacity of the filter element, the diameter of the largest hard spherical particle that the filter can pass under the specified test conditions is often used as its absolute filtration accuracy to directly reflect the initial filtration of the new filter element. ability.

The most important criterion for evaluating hydraulic oil filter elements is the β value measured according to ISO4527-1981E (multi-pass test), that is, the oil mixed with the standard test powder is circulated through the oil filter multiple times, and the oil inlet and outlet are on both sides The ratio of the number of particles.

(2) Flow characteristics The flow and pressure drop of the filter element through the oil are important parameters of the flow characteristics. The flow characteristics test should be carried out according to the ISO3968-91 standard to draw the flow-pressure drop characteristic curve. Under the rated oil supply pressure, the total pressure drop (the sum of the pressure drop of the filter housing and the pressure drop of the filter element) should generally be below 0.2MPa.

(3) The strength of the filter element should be subjected to a rupture-impact test according to the ISO2941-83 standard. The pressure difference that drops sharply when the filter element is damaged should be greater than the specified value.

(4) Flow fatigue characteristics shall be subjected to 100,000 cycles fatigue test according to ISO3724-90 standard.

(5) The test of hydraulic oil should be tested according to ISO2943-83 standard to withstand the pressure flow to verify the compatibility of the filter material with the hydraulic oil.