Contact us

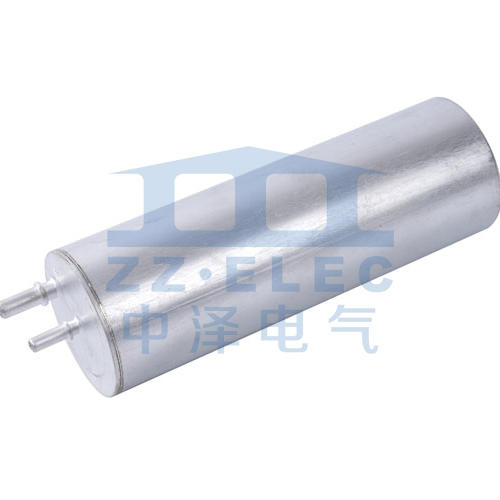

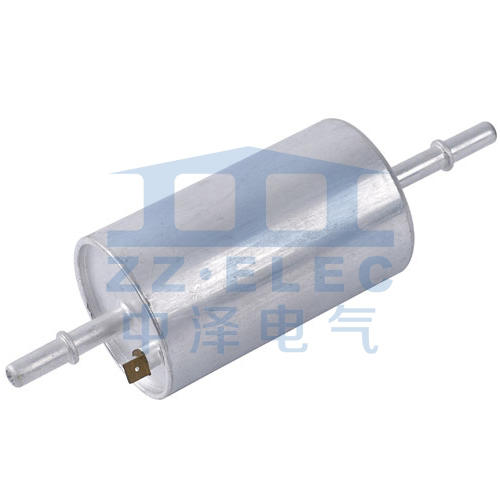

High quality VW IMPORT FILTER

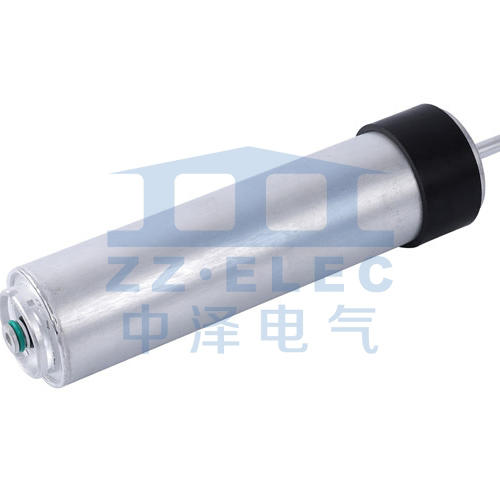

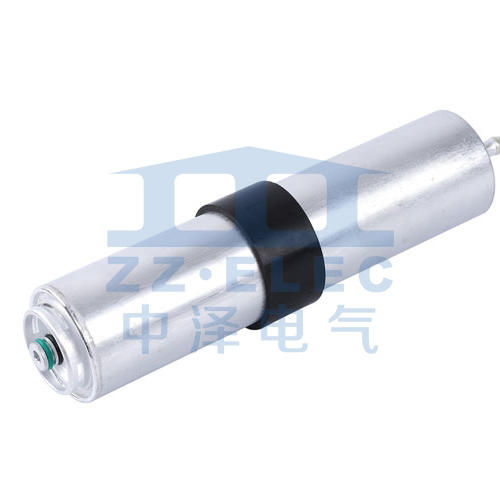

Brand BMW FILTER

BMW (Import) 8 (E31), BMW (Import) ...

Daewoo (import) REXTON (GAB_), Volk...

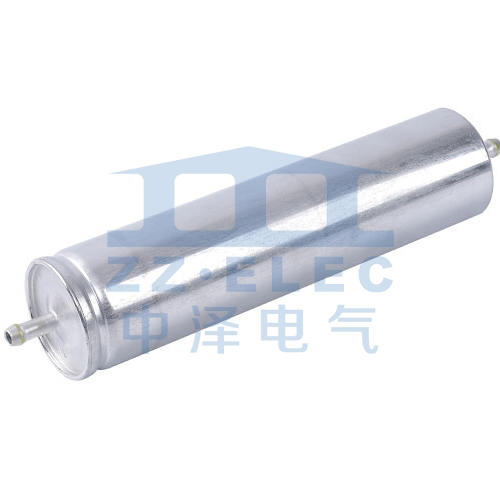

FORD(2011Focus) Filter

Fiat Filter

Fox Filter

Ford (import) FOCUS / Mazda (import...

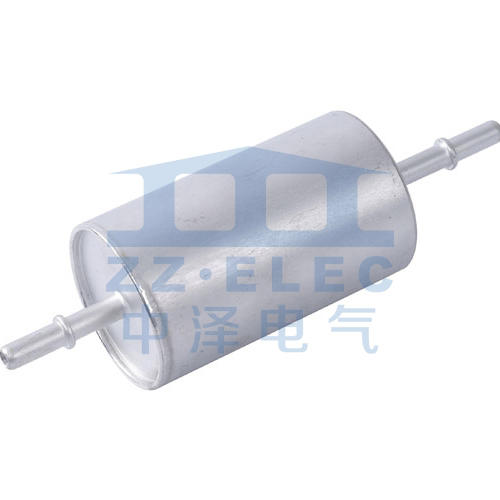

POLO Filter

BMW-X1(E84)、X3、X4 Filter

LAND ROVER RANGE ROVER FILTER acces...

High precision SSANGYONG FILTER

Low price BMW-E65, E66, E760 FILTER

High efficiency SSANGYONG FILTER

Professional Export POLE PIECE

RUST COLOR POLE PIECE-15

Zhejiang Zhongze Electric Co., Ltd is a famous aluminium cold extrusions manufacturers and , our group has four production-type subsidiaries, which were first established in 1987 and started with precision cold extruded aluminum products and precision injection molded products.

Tel: +86 0573-82696969

Phone: +86 13957386455 13819772766

Fax: +86 573 82696982

E-mail: [email protected]

Add: 379 Yinhe Road, Jiaxing City, Zhejiang Province,China

Copyright © Zhejiang Zhongze Electric Co., Ltd. Rights Reserved. China Lithium battery Components Factory