Various types of

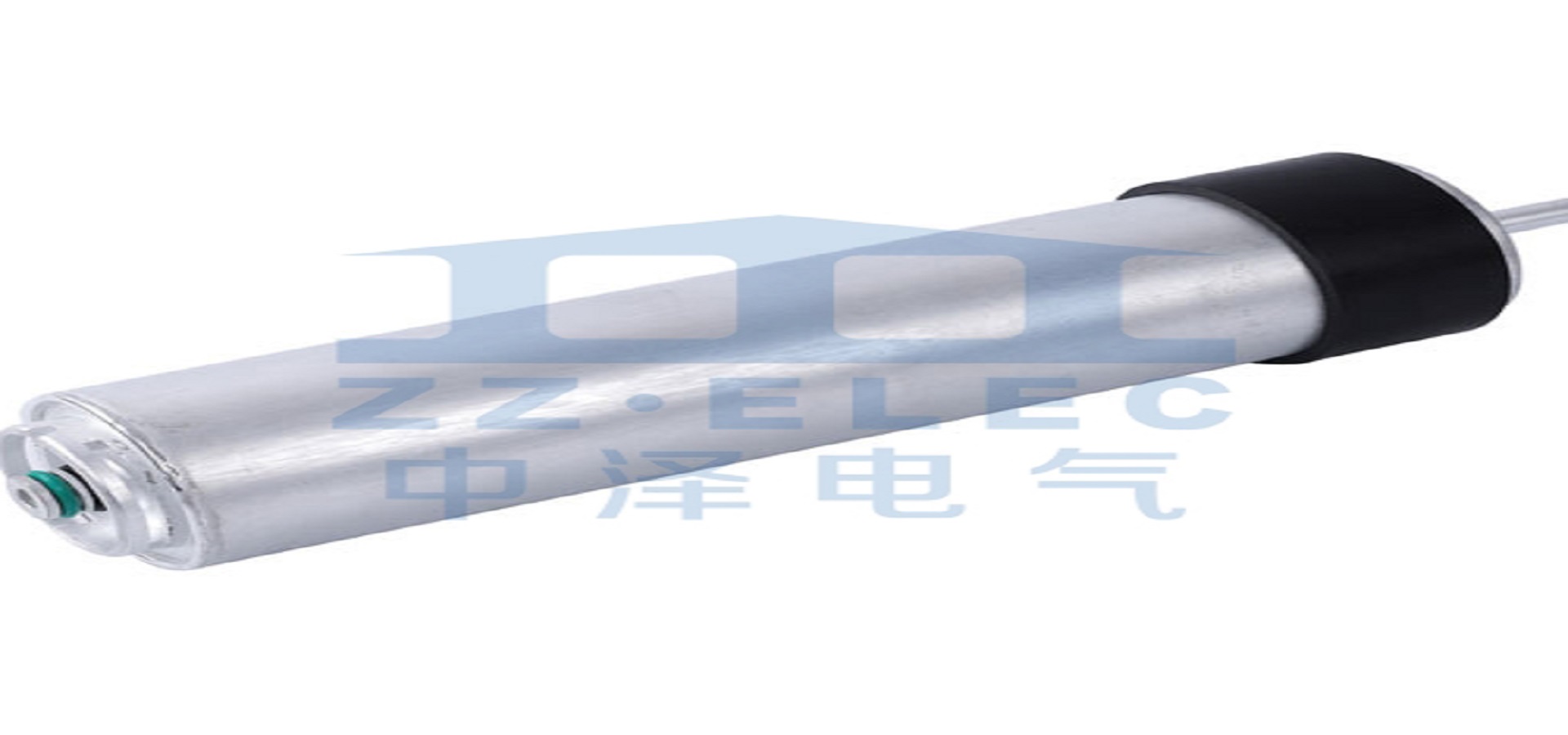

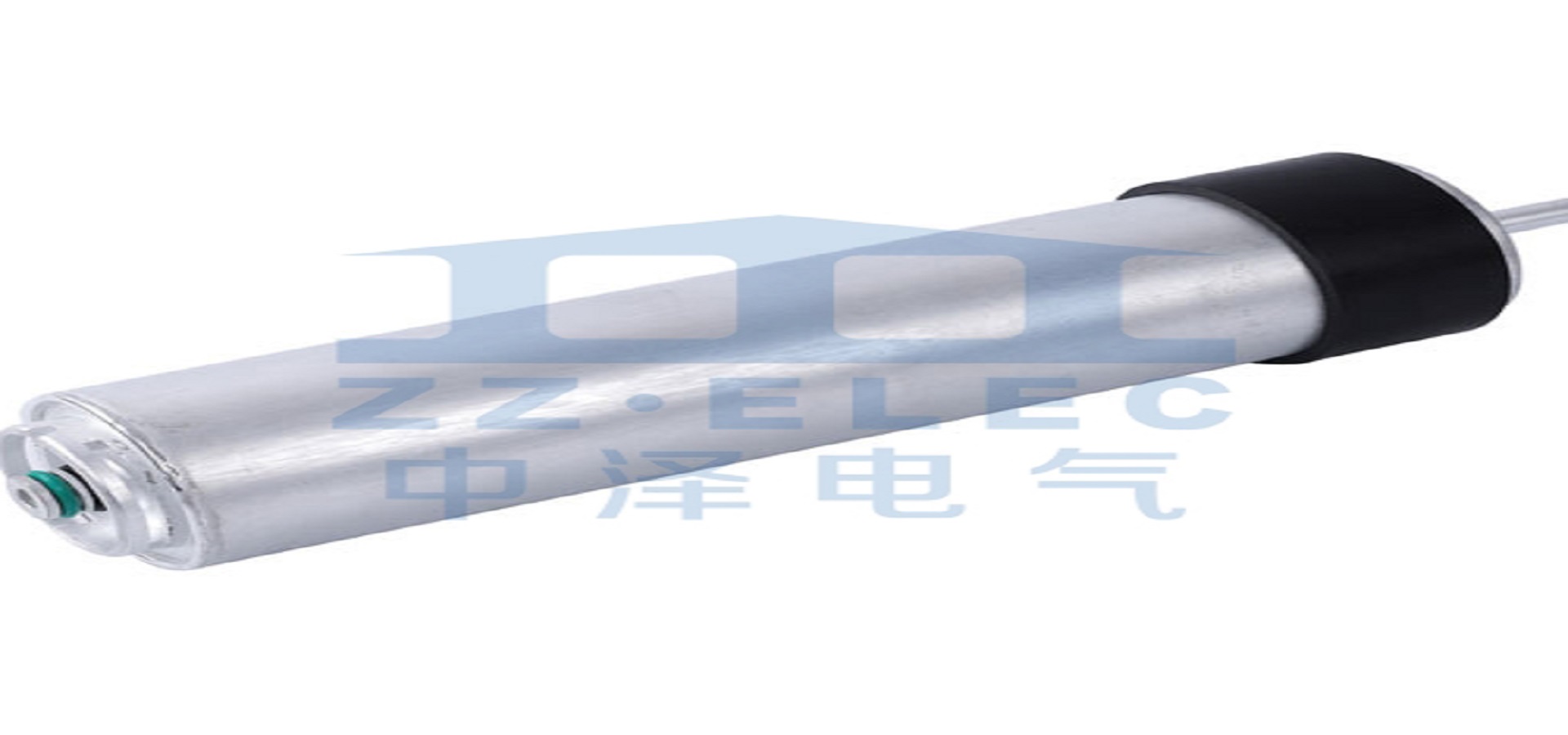

aluminium electrolytic capacitor components are used in power electronics applications. Aluminum electrolytic capacitors are typically used in industrial power supplies and DC-DC converters. These capacitors are also used in power factor correction and filtering AC power supplies.

Electrolytic capacitors have been used in radio broadcasts since the early 1900's. Aluminum electrolytic capacitors are the type of capacitor. However, they have inferior temperature and frequency characteristics to polymer capacitors. They also have a high failure rate. In order to avoid early failures, manufacturers of aluminium electrolytic capacitors provide end of life criteria. These criteria compare actual values to initial values.

The electrolyte used in aluminum electrolytic capacitors is a mixture of solvents and salts. Common solvents include ammonium salts and ethylene glycol. The electrolyte is sealed in a container to prevent evaporation. When the electrolyte evaporates, it can result in a decrease in performance.

Aluminum electrolytic capacitors are available in a variety of sizes and voltage ratings. The voltage range is between 5 Vdc and 700 Vdc. They are polarized, which means that one aluminum foil is a cathode, while the other aluminum foil is an anode. The anode foil is roughened to increase its surface area, which produces a higher capacitance.

Electrolytic capacitors can be used in high-current, low-frequency circuits. In addition, they are useful in audio amplifiers and as coupling capacitors. However, they must be used properly. They must be forward-biased to ensure that they function properly. A reverse-bias can result in a short circuit between the capacitor terminals and an overheating or electrolyte leakage.