Contact us

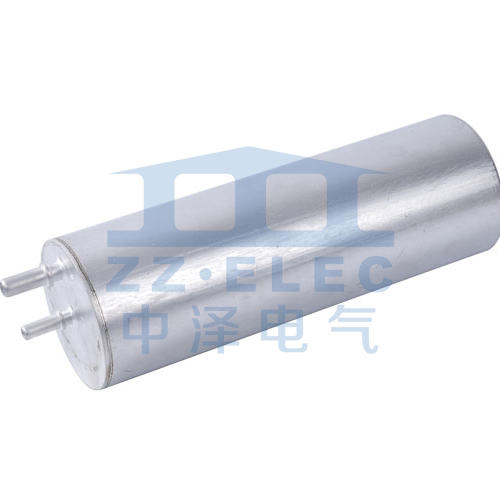

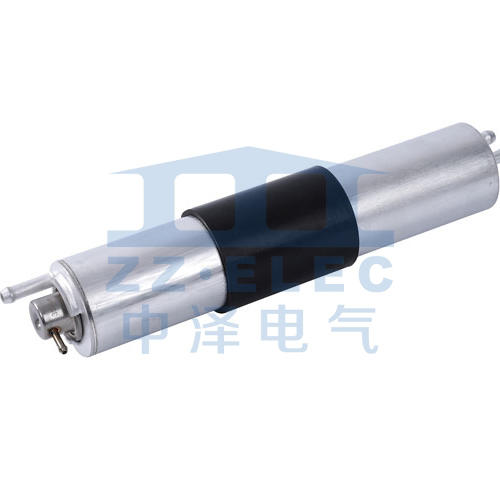

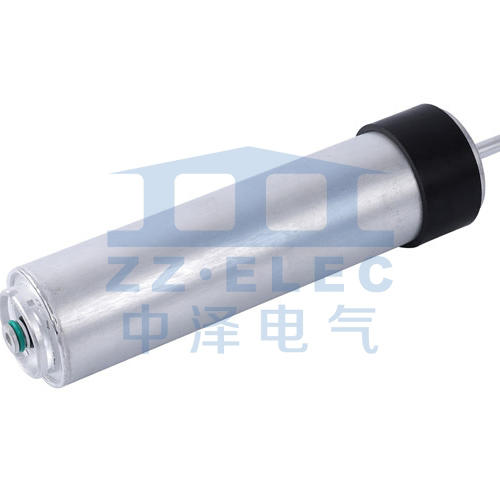

The electric fuel pump consists of a pump body, a DC motor and a housing. Its basic working principle is that after the DC motor is energized, the rotor in the pump casing is driven to rotate at a high speed, and the cut surface of the lower end of the rotor shaft is combined with the inner hole cut surface of the impeller, so that when the rotor rotates, the impeller rotates in the same direction through the rotor shaft. During the high-speed rotation of the impeller, a vacuum low pressure is generated in the oil inlet portion, and the filtered fuel is sucked from the oil inlet of the pump cover.

The sucked fuel is pressurized by the fuel pump impeller and then enters the pump casing and then passes through the oil outlet. Out, provide fuel with a certain pressure for the fuel system. The structure of the DC motor includes a permanent magnet fixed to the inner wall of the casing of the pump casing, a rotor capable of generating a magnetic moment after being energized, and a graphite carbon brush assembly mounted at the upper end of the casing. The carbon brush is in elastic contact with the commutator on the armature rotor, and the lead wire is connected to the plug wire electrode of the outer casing, and the outer ends of the electric fuel pump pump casing are crimped and crimped to become a non-detachable assembly.

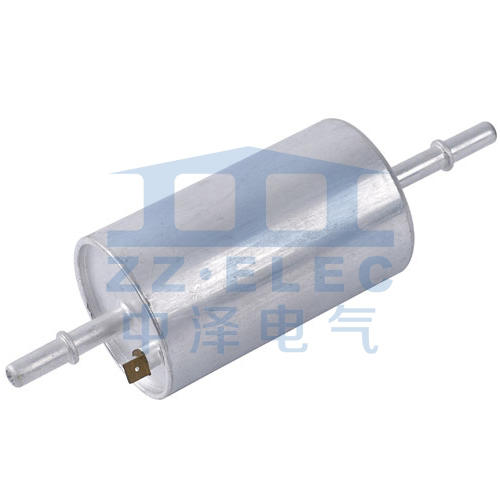

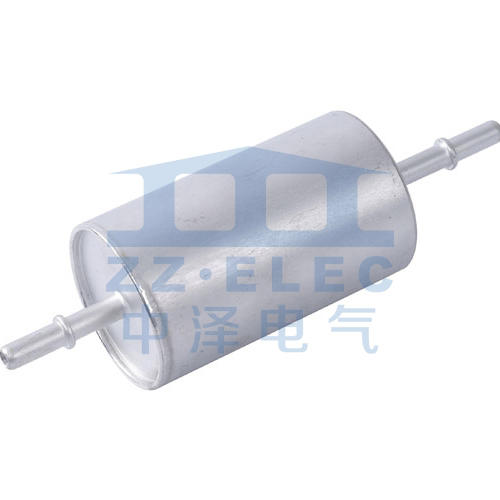

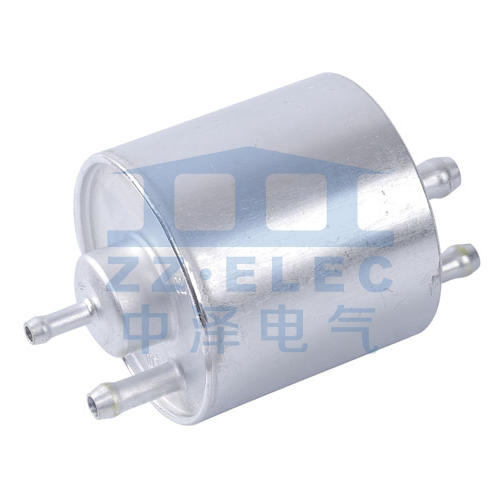

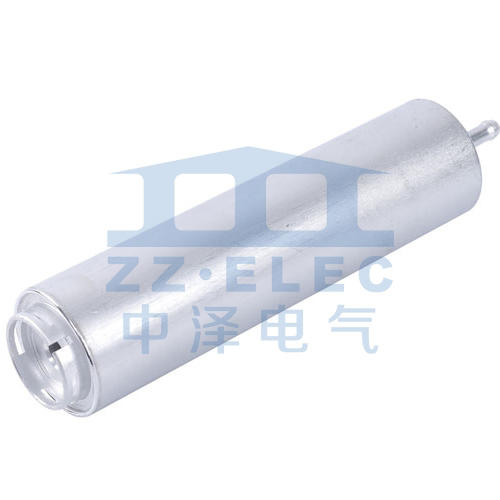

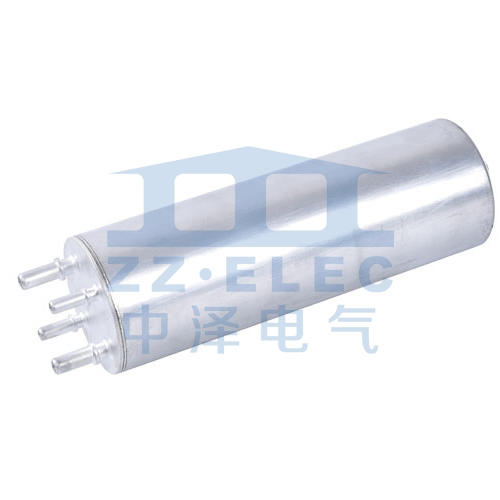

Fuel pump housing

Efficient VW IMPORT FILTER

BMW (import) Z3 Filter

Brand BMW FILTER

Land Rover (import) FREELANDER (LN)...

FORD(2011Focus) Filter

Ford (import) FOCUS / Mazda (import...

Multi-effect BMW FILTER

Mercedes Filter

Direct Sales BMW (IMPORT) 3 FILTER

Volkswagen VW Touareg Filter

High precision SSANGYONG FILTER

Professional production BORA FILTER

High efficiency SSANGYONG FILTER

New energy super capacitor componen...

RUST COLOR POLE PIECE-15

Zhejiang Zhongze Electric Co., Ltd is a famous aluminium cold extrusions manufacturers and , our group has four production-type subsidiaries, which were first established in 1987 and started with precision cold extruded aluminum products and precision injection molded products.

Tel: +86 0573-82696969

Phone: +86 13957386455 13819772766

Fax: +86 573 82696982

E-mail: [email protected]

Add: 379 Yinhe Road, Jiaxing City, Zhejiang Province,China

Copyright © Zhejiang Zhongze Electric Co., Ltd. Rights Reserved. China Lithium battery Components Factory